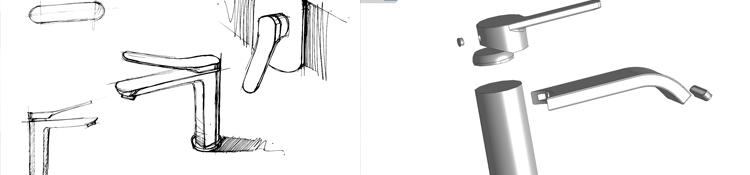

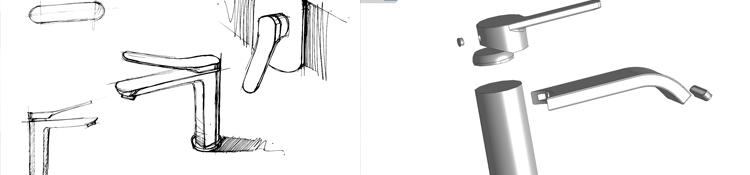

Design and Development

Faucet design is not only the appearance of the pursuit but also the innovation and functionality consideration. Our designer teams are all skilled designers and engineers. With their teamwork, we can always create original and aesthetically pleasing faucet designs and transform these designs into precise molds.

Thanks to the developing team and new technology, we can arrange fast development and 3D prototypes, which makes the development process fast and efficient.

Core Shooting Machine

Increasing demands on casting quality and the trend to thin-walled structures for high-performance faucets have led to stricter requirements on the quality, and at the same time, greater geometrical complexity of sand cores. We design and produce sand cores in our production site which will help us control the quality well.

High-grade Raw MaterialsMost of our faucets are made of brass materials by means of casting. Yuson's faucets use high-quality brass H59 or lead-free brass. Of course, there are faucets made of other materials, such as stainless steel 304, stainless steel 316l, and also zinc alloy. Stainless steel is somewhat lead-free, but has a high melting point and is not easy to form during production and aesthetic designs are limited.

Gravity Casting

We have our professional gravity casting machinery, and giving more precision over each pour increases the efficiency and product quality.

During the gravity casting process, molten brass is poured into the molds, and then put it into water to cool down. This method allows for precise shaping of the faucet body, ensuring a flawless and solid body.

Peeling Off Polishing and CNC Machining Process

After casting, the faucet bodies are put on the peeling-off machines to peel off the initial surface, which could help a lot for the mutual polishing process, and also refined using CNC machines. The CNC machining process is crucial for ensuring that every edge and thread is perfect, aligning with our original designs.

Casting Body Leakage Testing

Mutual Polishing

Assembling and Testing, 100% Water Test

After the casting of the faucet is electroplated and passes the inspection, it can enter the assembly process. Assembly is the process of connecting processed faucet parts in a certain order and technology to become a complete faucet product and reliably realize the function of product design. Assembly is at the final stage necessary for the manufacture of the product, and the quality of the product (from product design, and part manufacturing to product assembly) is finally guaranteed and tested by assembly.

Quality Control During Every ProcessAt every process in faucet production, there are quality control processes in site, whether through physical testing or laboratory inspection. Each of our machines is certified to maintain their precision in order to deliver consistent quality.

Surface TreatmentsSurface treatment is not just about aesthetics; it’s about durability. Our faucets undergo various treatments, including polishing, plating, and coating, to ensure they are resistant to tarnish and corrosion. This step is crucial in maintaining the faucet’s appearance and functionality over time.

The surface treatment process mainly includes PVD (Physical Vapor Deposition), ORB (Oil Rubber Bronze), plating, etc. The most widely used faucet is electroplating chromium. Electroplating can enhance the corrosion resistance of the faucet, increase the hardness, prevent wear, and increase the appearance of the surface.

CNAS Standard LaboratoryAt our CNAS standard laboratory, we have systemic and professional equipment to control quality and arrange testing according to different standards, complying with different countries' requirements. At every stage, our products have to pass strict testing requirements. We need to ensure that each faucet lives up to our standards.

The equipment list as below

Salt Spray Test Machine: ASS, NSS, CASS.

Thermostatic EnduranceTest Machine: Testing the functional life of thermostatic cartridges and valve cores.

High-Pressure Burst Test Machine: High-pressure burst testing of faucets, hoses, valves, and pipelines.

Tensile Testing Machine: Tensile strength, hanging load, and bending test of hoses.

Flowrate Test: Flow rate testing of individual top sprays, handheld sprays, spray guns, and entire sets of faucets.

Fully Automatic Burst Strength Tester: Paperboard burst strength testing.

Intelligent Compression Strength Testing Machine: Compression strength testing of paperboard including ring crush strength, edge crush strength, and adhesive peel strength.

High-Temperature Drying Test Chamber: Surface treatment of metals such as copper, zinc alloy, and stainless steel.

Comprehensive Testing Machine: Functional testing of valve cores including safety, pressure variation, repeatability, sealing, flow rate, and temperature.

Hard Water Test Machine: Testing the anti-scaling ability of handheld and top spray showers.

Spectrometer:

1. Material analysis of copper, zinc alloy, and stainless steel.

2. Composition testing of chromium, nickel, and copper on surfaces electroplated with various materials.

Constant Temperature and Humidity Test Chamber: Testing freeze-thaw cycles and thermal cycling of plastic products.

Standard Faucet Life Test Machine: Testing single-handle single-control, single-handle dual-control, and push-button faucets.

Hot and Cold Fatigue Test Machine: Immersion and thermal cycling tests with temperature variations.

Low-Pressure Flow Test Machine: Ultra-low pressure testing from 0.1 to 0.2 bar.

Sand Abrasion Test Machine: Testing the resistance to particle damage for organic coated products.

Thermal Cycling Test Machine: Thermal cycling tests for handheld showers, top spray showers, and hoses.

Pulse Test Machine: High and low-pressure testing of hoses and faucets.

Valve Core Life Test Machine: Testing the functional life of quick-opening valve cores and constant temperature valve cores.

Jetting Force Tester: Testing the maximum average jetting force of handheld showers.

Load Resistance Equipment: Testing the load resistance of constant temperature faucets, standard faucets handwheels, or handles.

English

English España

España

.jpg?imageView2/2/w/320/h/320/format/jpg/q/75)